top of page

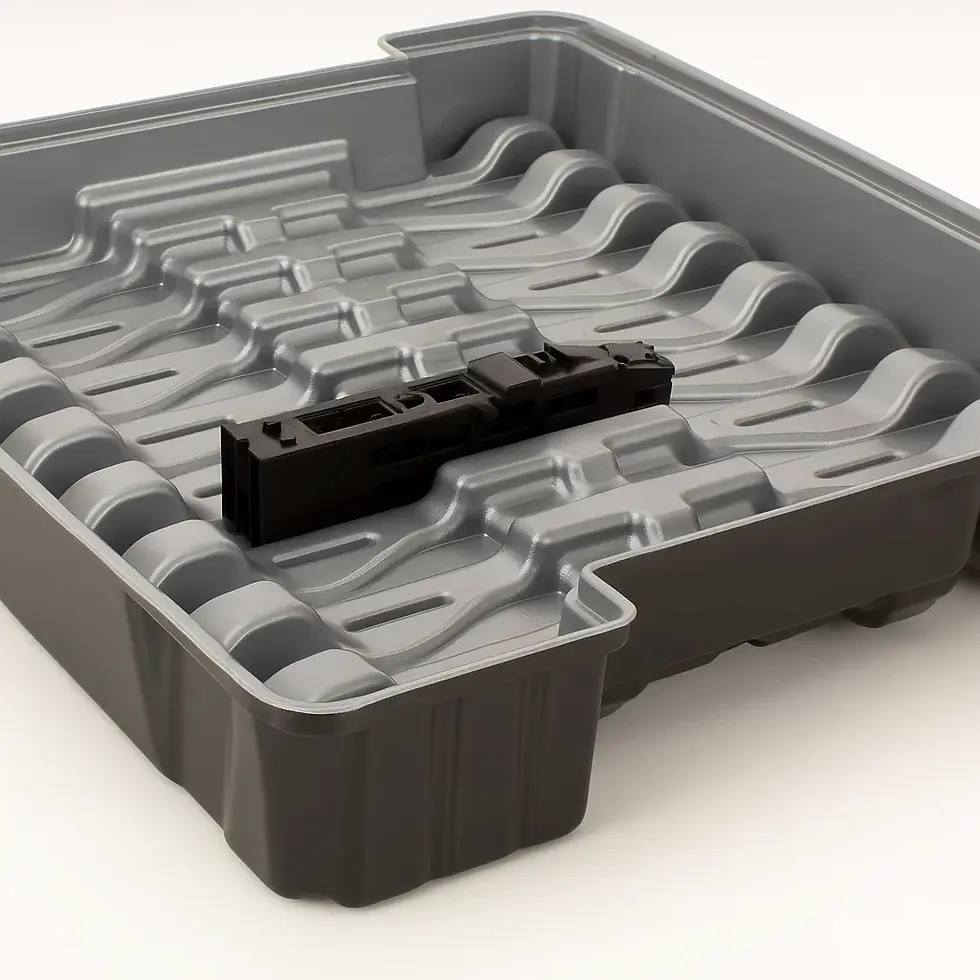

Thermoforming with 3D-Printed Molds

Fast Flexible Cost-efficient

We’re transforming the thermoforming process using high-resolution 3D-printed molds. Instead of conventionally milled metal tools, we produce molds using additive printing technology. This allows extremely short lead times and significantly lower costs—ideal for prototyping, small batches, and design validation.

Key Advantages:

-

Tool production in just 1–2 days

-

Complex geometries at no extra cost

-

Lower cost than CNC-milled molds

-

Compatible with ABS, PS, PETG, and more

-

Quick design iterations via digital workflow

Applications:

Packaging, housings, covers, trays, and more—produced rapidly using 3D-printed molds.

bottom of page